Sojitz Wood Procurement Policy

Based on the “Sojitz Group Supply Chain CSR Action Guidelines,” Sojitz set a “Wood Procurement Policy” for responsible wood procurement in September 2015.

Sojitz Wood Procurement Policy

In honoring the Sojitz Group Statement, we are committed to do our best to cooperate with business partners to procure wood in line with the following policies, based on the Sojitz Group CSR Action Guidelines for Supply Chains.

- Legality

We will not handle wood obtained through illegal logging. - Environmental Consideration

We will not handle wood obtained through logging methods which are detrimental to high conservation value forests, and we aim to build a supply chain which allows for no deforestation.* - Social Consideration

In view of logging’s potential to adversely impact human rights, we will seek to mitigate any negative impact associated with wood procurement.

- “No deforestation” is defined as no conversion of natural forests and no damage to high conservation value forests. “Conversion of natural forests” is defined as the conversion of natural forests to tree plantations or other non-forest land use after December 31, 2020.

<Scope>

This policy covers all roundwood; sawnwood and wood-based panels; wood chips; paper and pulp; and woody biomass handled by Sojitz and its consolidated subsidiaries (hereafter, “wood.”)

Implementation

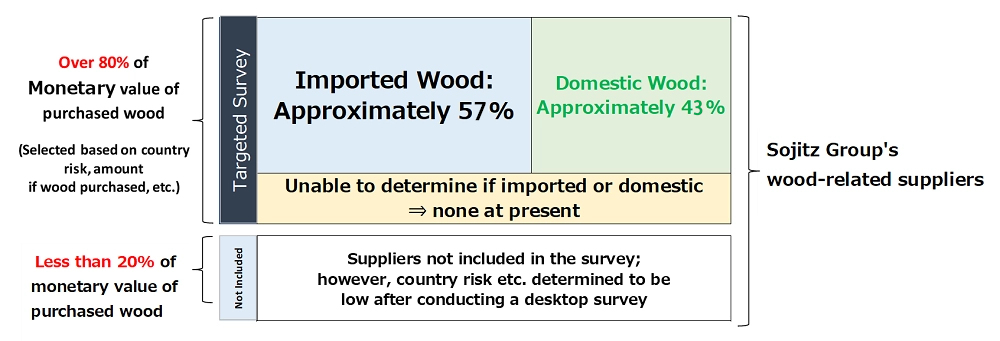

We selected and conducted a targeted survey of wood that makes up over 80% of our total purchased wood supply in terms of monetary value (*1), using criteria including the supplier country’s risk level (*2), the amount of wood purchased in terms of monetary value, and suppliers’ compliance with Sojitz policies, from among Sojitz Group’s approximately 1,500 wood-related suppliers (*3).

The survey conducted in the 2024 fiscal year found that of the surveyed wood supply, 57% was imported wood, and 43% was produced domestically. We take an approach to surveying that accounts for the unique characteristics of both the import and domestic industries.

- The amount surveyed is at least 80% of purchases, excluding Group companies and discontinued suppliers.

- Our country risk evaluation adopts the Corruption Perceptions Index made available by each year by Transparency International, an international non-governmental organization working to prevent corruption around the world. This index ranks countries individually by comparing levels of corruption among public servants and politicians.

- Details of the scope of Sojitz Group’s wood procurement survey are as follows.

| Product | Sojitz Corporation | Sojitz Building Materials Corporation | Sojitz Kyushu Corporation |

|---|---|---|---|

| Round wood | ○ | ||

| Woodchips | ○ | ○ | |

| Lumber products | ○ | ○ | |

| Veneer

|

○ | ||

| Plywood | ○ | ○ | |

| Paper and pulp | ○ | ||

| Pellets | ○ | ||

| Fiberboard | ○ | ○ | |

| Engineering wood | ○ | ○ | |

| Building materials | ○ | ○ | |

| Pre-cut wood | ○ |

- Note: Product definitions are as follows.

- Lumber products:Including lamina

- Paper and pulp:Sold as main products

- Fiberboard:OSB, MDF, particleboard

- Engineering wood:Including LVL, CLT, and panel boards

- Building materials (solid wood):Internal construction materials such as fittings, fixtures, flooring materials, and paneling

- Building materials(overseas products):Products produced by overseas manufacturers

- Pre-cut wood:Structural and paneling materials

Approach to Imported Wood

Sojitz recognizes various issues regarding imported wood, such as illegal logging, human rights violations against local communities, and threats to biodiversity in certain areas.

Sojitz Group is working together with each supplier to monitor and improve the legality of logging practices as well as the consideration for the environment and society in areas where logging takes place, as outlined in the Sojitz Wood Procurement Policy.

Sojitz will continue its efforts to raise awareness among its suppliers by providing examples of best practices for wood procurement. In addition, Sojitz seeks to develop and improve the capabilities at these organizations to ensure wood procurement is in line with environmental and social considerations.

Survey Methods

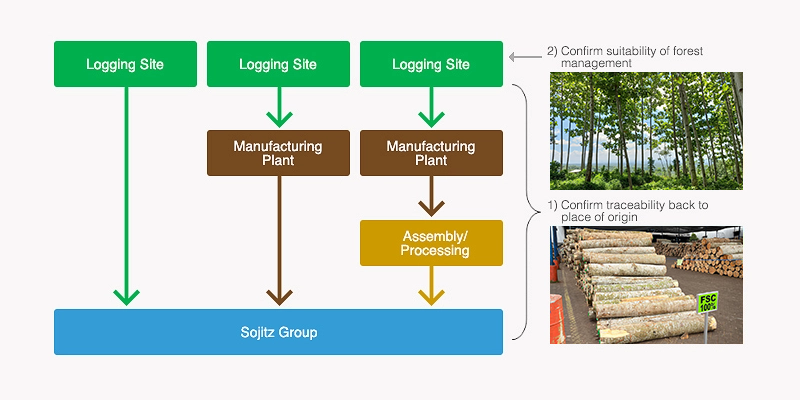

Under the supervision of WWF Japan (*4), the wood selected for survey was checked for 1) traceability to its country of origin, and 2) suitability of forest management (whether the forest is subject to environmentally/socially conscious forest management).

- *4:We have adopted use of WWF Japan’s “Responsible Purchasing Checklist for Forest Products” to confirm 1) wood traceability in the country of origin and 2) suitability of forest management. We also invited WWF to hold a briefing session in FY2015 to explain how to confirm whether forests with high conservational value in terms of biodiversity are being appropriately protected, as well as how to define human rights issues. Sojitz's lumber-related departments and subsidiaries attended the lecture. Furthermore, we referred to advice from WWF Japan in establishing the targets below.

Evaluation Criteria

Wood was evaluated for 1) traceability back to the place of origin and 2) suitability of forest management, after which it was sorted into one of the following four levels.

Level A:Wood confirmed to be certified wood (*5)

Level B:Wood which has not been certified, but for which we have verified both traceability and suitability of forest management (i.e. that the forest is subject to environmentally/socially conscious forest management)

Level C:Traceable wood

Level D:Wood lacking traceability

- *5:Wood certified under FSC®, PEFC, etc. FSC®-certified wood is given the highest score.

For reference: Sojitz Corporation’s FSC® license code is FSC-C009917

Targets & Results

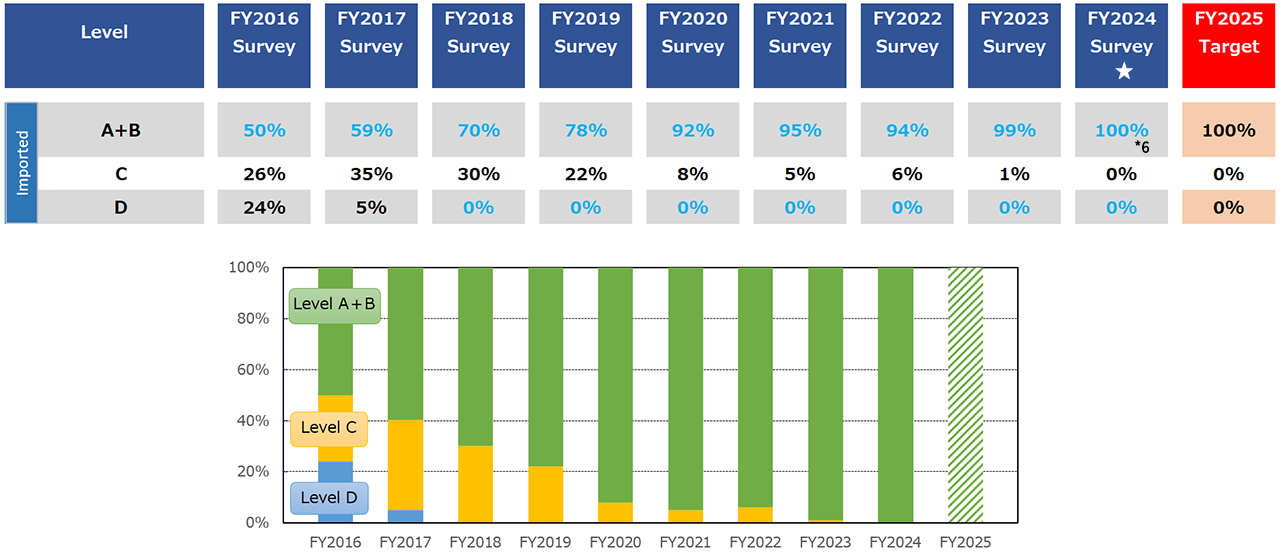

Target for FY2025

Building upon our successful completion of the FY2020 goal, Sojitz has established the following target for FY2025.

Sojitz Group will ensure that by FY2025, 100% of the wood we handle is either certified wood (Level A), or wood that has not been certified, but that we have verified as being procured through environmentally/socially-conscious methods (Level B).

Maintain 100% traceability as per our FY2020 goal

Quantitative Progress and Sojitz’s Target

- *6:From the FY2020 survey onwards, we limit the category to only wood that has been officially certified. (Level A wood made up 18% in the FY2024 survey.)

- Levels A through D were determined based on evaluations conducted by Sojitz using WWF Japan’s “Responsible Purchasing Checklist for Forest Products”. Percentages in the above table were calculated by dividing “the cost of procured (imported) wood in each level” by “the total cost of all imported wood included in the survey”. The FY2024 survey is calculated from the amount of procured wood in FY2023.

We achieved our FY2025 target (100% Level A+B wood) ahead of schedule in FY2024. Moving forward, we will continue to undertake the following initiatives to maintain this target.

Overview of initiatives

- Traceability surveys before initiating trade

We conduct surveys on traceability and environmental/social consciousness before initiating trade with new potential suppliers based on factors such as the country risk level of the supplier's products. - Periodic due diligence (annual survey)

During the annual survey to assess traceability and the supplier's environmental and social considerations, we conduct on-site visits to suppliers as necessary.

In FY2024, we conducted 21 on-site visits: 4 in Indonesia, 4 in China, 3 in Malaysia, 1 in Thailand, and 9 in Vietnam. - Increase quantity of certified wood handled by Sojitz Group

In order to promote the wider adoption of forest certifications which contribute to sustainability in the timber and wood products industry, Sojitz Group will strive to expand its handling of materials with Chain-of-Custody (CoC) certification, which certifies the distribution channels of the materials.

* Chain-of-Custody (CoC) refers to forest products that have been properly managed during the processing and distribution process to ensure that they are not mixed with non-certified forest products. - Encourage business partners to obtain wood certification

We encourage our suppliers to obtain FSC, PEFC, or other forestry certifications, as well as Chain-of-Custody (CoC) certification which traces the distribution channels of forest products. We will encourage our secondary and tertiary suppliers to obtain certifications when conducting our annual survey on our wood procurement policy, and we also clearly state this request in our survey forms, guidance for suppliers, and other documents. - Promote the use of eco-friendly wood products to consumers

We will encourage our domestic customers to adopt environmentally friendly products and actively promote the use of these green products. - Conduct detailed on-site due diligence for suppliers

For suppliers with identified areas of concern, we conduct detailed on-site due diligence as necessary, either accompanied by external experts or in accordance with expert advice.

Past on-site due diligence record:

FY2017: 1 supplier; FY2018: 1 supplier; FY2019: 2 suppliers; FY2020 and FY2021: postponed due to COVID-19; FY2022:1 supplier; FY2023:1supplier; FY2024:postponed due to local security and other circumstances

We incorporate the results and findings of detailed on-site due diligence into our ongoing efforts to mitigate risk.

Third-party Assurance

To increase the objectivity of our calculations, Sojitz has acquired third-party assurance from KPMG AZSA Sustainability Co., Ltd. (KPMG) for the data detailed below since FY2020. The FY2024 data assured by KPMG is marked with star ("☆”) in the data table above.

〔Scope of Third-party Assurance〕

KPMG provides assurance as to whether the results of the survey conducted in FY2024 on procured (imported) wood described above are prepared, in all material respects, in accordance with the criteria established by Sojitz.

Reference:Target Achievement Results Prior to FY2020

Target:

Sojitz Group will ensure that 100% of the wood we handle is traceable (reduce wood classified as Level D to 0%) by FY2020.

Results:

We achieved our goal (reduce Level D wood to 0%) in FY2018 and successfully maintained 100% traceability for the following seven years.

Approach to Domestically-Produced Wood

<Basic Philosophy>

We recognize that domestically produced wood requires awareness of a different set of issues than imported wood, such as labor safety at logging sites and regional resource recycling. As we continue to encourage both our domestic and international suppliers to be aware of social and environmental issues, we are also working to develop distinct approaches for imported wood and domestic wood in order to address each individually.

Placing an emphasis on the recycling of resources in regions where wood is harvested, we will build community-based forestry through discussions with our stakeholders as we work to address these issues.

Approach to Forest Use for Business Projects

We take steps to verify that our business projects cause no negative environmental or social impact such as complying with all related laws and regulations, acquiring all necessary permits and licenses, and conducting environmental impact assessments third-party environmental and social due diligence in cases involving logging for projects such as mine development, power generation development, and industrial park development.