Introducing the Sojitz employees continually taking on new challenges to create new value for society

News Room

-

Feb. 9, 2026

Personnel Change

Sojitz Corporation Announces Changes to Personnel

-

Feb. 3, 2026

News Release

Consolidated Financial Results for the Third Quarter Ended December 31, 2025 (February 3, 2026)

-

Jan. 29, 2026

News Release

Sojitz Corporation Announces Organizational Reforms and Executive Appointments

-

Jan. 5, 2026

News Release

President’s New Year’s Address for 2026

-

Dec. 26, 2025

Topics

Royal HD, Choushimaru, and Sojitz Partner for Opening of Specialty Sushi Restaurant SUSHI NIGIRIBA in U.S.

-

Feb. 3, 2026

News Release

Consolidated Financial Results for the Third Quarter Ended December 31, 2025 (February 3, 2026)

-

Jan. 29, 2026

News Release

Sojitz Corporation Announces Organizational Reforms and Executive Appointments

-

Jan. 5, 2026

News Release

President’s New Year’s Address for 2026

-

Dec. 2, 2025

News Release

Sojitz Enters Australia’s Transport Sector

-

Nov. 26, 2025

News Release

Sojitz Acquires Electricity Retail Business in Australia

-

Dec. 26, 2025

Topics

Royal HD, Choushimaru, and Sojitz Partner for Opening of Specialty Sushi Restaurant SUSHI NIGIRIBA in U.S.

-

Oct. 30, 2025

Topics

Sojitz Begins Import of Heavy Rare Earths from Australia

-

Sep. 11, 2025

Topics

Notice Regarding Transfer of Equity Interest in North American Railcar Lease Business

-

Jan. 9, 2025

Topics

Sojitz Supports Turquoise Hydrogen Production Technology Development with Additional Investment in Hycamite TCD Technologies in Finland

-

Oct. 17, 2024

Topics

Installation of m-DAC® Technology in Tokyo to Capture and Utilize Carbon Dioxide from the Atmosphere

-

Jul. 11, 2025

Information

Sojitz Publishes Integrated Report 2025

-

Jun. 20, 2025

Information

Establishment of New Company by Sojitz Pla-Net and Pla Matels

-

Jun. 18, 2025

Information

Notice of Resolutions at the 22nd Ordinary General Shareholders’ Meeting

-

Jun. 16, 2025

Information

Annual Securities Report 2024

-

May 21, 2025

Information

The notice of the 22nd Ordinary General Shareholders’ Meeting

-

Feb. 9, 2026

Personnel Change

Sojitz Corporation Announces Changes to Personnel

-

Dec. 12, 2025

Personnel Change

Sojitz Corporation Announces Changes to Personnel

-

Dec. 8, 2025

Personnel Change

Sojitz Corporation Announces Changes to Personnel

-

Nov. 20, 2025

Personnel Change

Sojitz Corporation Announces Changes to Personnel

-

Oct. 10, 2025

Personnel Change

Sojitz Corporation Announces Changes to Personnel

-

Jul. 30, 2024

Group News Release

Phenix Jet Expands its Business Jet Services to Southeast Asia – Singapore Branch Starting Operation

-

Feb. 22, 2024

Group News Release

FoodTech One Corporation Established by 12 Food Industry Companies to Develop and Expand the Spread of Sustainable Food Products

Who we are A general trading company that constantly cultivates new businesses and human capital.

For more than 160 years, Sojitz has continued to advance innovative businesses globally in countries and regions including Japan, the U.S., Europe, the Middle East & Africa, China, and Asia & Oceania. Sojitz strives to discover the needs of each region to create new prosperity.

View detailsCorporate Information

View details

Advancing Towards

Sojitz’s Next Stage

Kosuke Uemura

Representative Director, President & CEO

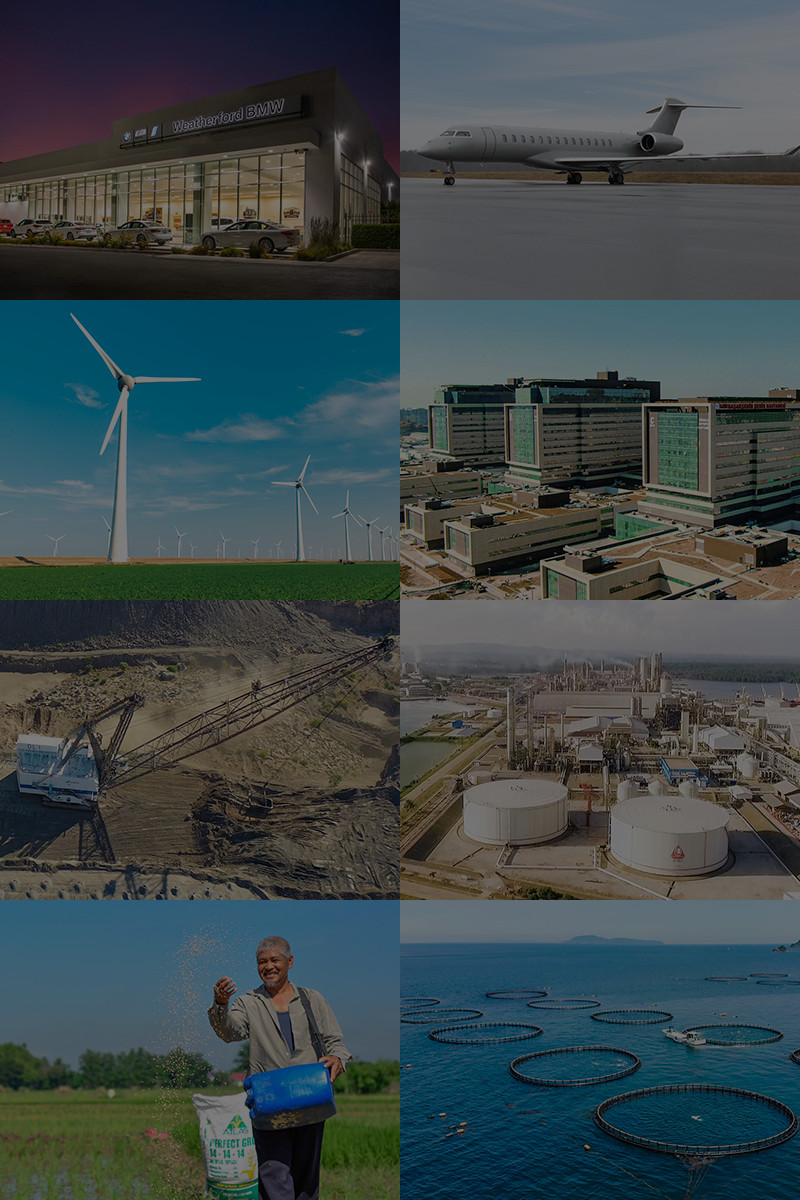

Our Business

Sojitz is engaged in a wide range of businesses as a general trading company, with projects in many different countries and regions around the world. We have seven divisions, organized according to function, industry, and product. Each division will work to stay one step ahead in anticipating social needs to create quality business opportunities.

View detailsFeatured Business Projects

Introducing Sojitz’s business projects, which highlight the company’s initiatives to create new value and prosperity around the world.

-

Investor Relations

Sojitz Corporation’s shareholder and stock information, procedures for purchasing treasury stock, articles of incorporation, and stock handling rules

View details -

Integrated Report / Annual Report

Sojitz Corporation’s integrated reports provide comprehensive explanations of the company’s value creation story, corporate strategy, business initiatives, and financial information.

View details

Sustainability Creating

Two Types of Value

for a Prosperous Future

For Sojitz Group, sustainability is our commitment to maximize two types of value—"Value for Sojitz” and “Value for Society”—through our business activities alongside stakeholders with the aim of realizing sustainable growth for both Sojitz Group and society.

View details