Sojitz and Canada’s SaskPower to Conduct Joint CCS Project CSS Memorandum Signed

Feb. 15, 2010

Sojitz and Canada’s Saskatchewan Province-owned Saskatchewan Power Corporation (SaskPower) signed a memorandum to jointly conduct a carbon capture and storage (CCS) project. This is the first time that a Japanese company has concluded a memorandum for commercial development of a CCS business package.

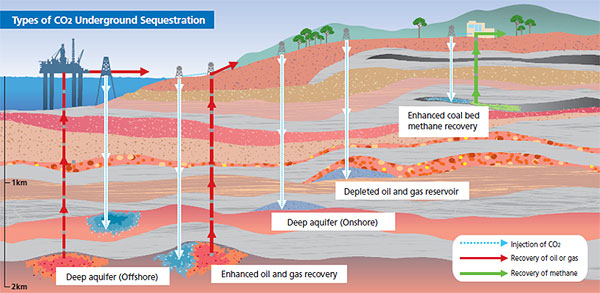

[Source: CO2 Underground Sequestration, IPCC (Intergovernmental Panel on Climate Change)]

CSS is a technology that seeks to limit the release of carbon dioxide into the atmosphere by capturing and recovering carbon dioxide from the emissions of thermal electric power plants and other similar facilities and storing it underground. Practical application of this technology is expected to be an important option to cope with the global warming issue.

Coal-fired power plants, which have relatively high levels of carbon dioxide emissions, accounts for half of SaskPower’s generating capacity, and an additional 4100 megawatts of generating capacity is planned for the next 20 years. As a result, it is necessary for SaskPower to reduce carbon dioxide emissions by raising the efficiency of coal-fired plants and by processing (storing) carbon dioxide that is emitted. In Saskatchewan Province, aquifers and oil fields suitable for carbon dioxide sequestration are located near coal-fired power plants in Estevan, making the site extremely attractive for a CCS project.

[The power plants in Estevan are located approximately 150 km southeast of Regina, the provincial capital and are situated in about the center of the oil fields.]

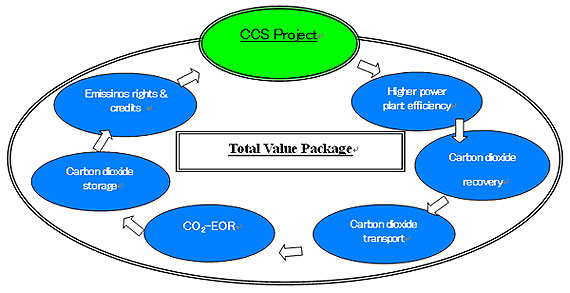

Sojitz will make use of its 40 years' experience in coal liquefaction technologies and business development to implement the CCS project. Under the project, Sojitz will submit a total value package that raises the efficiency of coal-fired power plants, an essential element of the project, and combines carbon dioxide recovery technology, transport and sequestration of recovered carbon dioxide in aquifers and oil fields, purchase and sale of carbon dioxide emissions rights, and carbon dioxide enhanced oil recovery (CO2-EOR) that raises economic performance. World-leading Japanese technologies will be employed for this project, and a consortium of Japanese enterprises is a possibility.

Sojitz and SaskPower will complete a grand design for CCS in 2012 while developing CO2-EOR and means of transport for carbon dioxide that it will recover starting in 2013 under a large-scale CCS trial that SaskPower is currently implementing. The project is scheduled to begin in 2013.

Reference

Conceptual Image of the Total Value Package

CO2-EOR

It is a tertiary recovery technology that increases crude oil recovery rates by injecting carbon dioxide into depleted oil fields. Approximately 20% to 30% of reserves can be recovered from oil fields through primary recovery under the pressure of the oil and secondary recovery by injecting water. Tertiary recovery by injecting carbon dioxide can improve crude oil recovery rates to approximately 50%

(The efficiency of carbon dioxide injection, however, is limited to medium-light oil).

Overview of SaskPower

| Name: | Saskatchewan Power Corporation |

|---|---|

| Address: | 12W, 2025, Victoria Avenue, Regina, Saskatchewan, Canada |

| Representative: | Mr. Garner Mitchell, acting president and CEO |

| Capital: | $1.529 billion Canadian (end of 2008) |

| Generating capacity: | 3600 megawatts (half from coal-fired power plants) (4200 megawatts will be added in the next 20 years, half of which will be from coal-fired plants) |

| Power lines: | 156,000 km |

| URL | http://www.saskpower.com/ |

SaskPower’s CCS Demonstration Project

With the support of the Canadian federal government and the provincial government, SaskPower will invest approximately 100 billion yen to modernize aging coal-fired power plant facilities and install carbon dioxide recovery facilities. Under this project, SaskPower is conducting a large-scale CSS demonstration to recover 1 million tons of carbon dioxide annually from a 150 megawatt coal power plant starting in 2013.